Development of a methodology for the extension and deflection-based calibration of an axis position-sensitive process force model

The research project "Development of a methodology for the extension and deflection-based calibration of an axis position-sensitive process force model" is a cooperation project between the Institute of Machining Technology of the Faculty of Mechanical Engineering and the Virtual Machining working group of the Faculty of Computer Science.

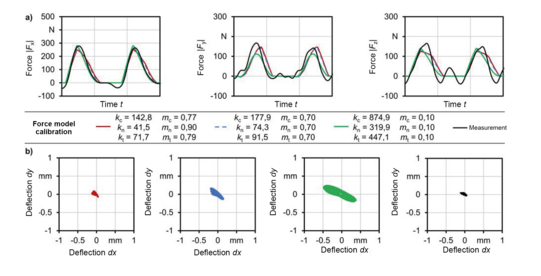

Process simulations can be used to analyze milling processes, for example to predict regenerative vibrations or to adjust process parameter values so that productivity can be increased and the required workpiece quality can be ensured. For example, models for calculating process forces and analyzing process dynamics are used in geometric-physical process simulations. Empirical cutting force models can be calibrated based on force measurements from cutting tests, although the dynamic behavior of the tool and the workpiece directly influences the measured cutting force as a disturbance variable. The force measurement technology used also restricts the implementation of force model parameterization due to its compliance and transmission behaviour. At the same time, different parameter value combinations can lead to different, comparably valid modeling, which results in different deflections in the simulation.

The transmission behavior of end mills on tools with spherical form elements, such as ball nose or torus cutters, especially with regard to the varying cutting edge shape and the local, effective helix angle, which influence the direction of force action and the specific cutting forces depending on the material, have not yet been comprehensively investigated.

In this project, a new methodology for the parameterization of process force models and subsequently an extended force model will be developed, taking into account the tool deflections measured during machining, in order to enable a clear prediction of exciting process forces and tool deflections, taking into account their physical interactions and the compliance of the system.

Based on an initial empirical parameterization, deflection measurements will be used to optimize the parameters. The tool orientation, the varying engagement conditions along the cutting edge and the transferability of the model calibration to other materials (using the example of steel and aluminum materials) and tools are to be investigated so that the validity range of the models is also extended with regard to the tool orientation of the axis position-dependent behavior in 5-axis milling processes.