Simulation-based design and manufacture of variable edge geometries along the cutting edges on cutting tools

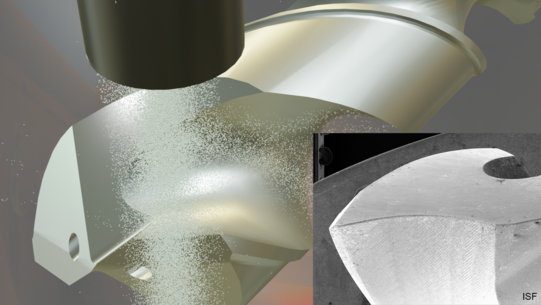

The shape of cutting edges during machining has a significant influence on process results, productivity and safety. The shape of the tool cutting edges after grinding, which is present during the manufacture of tools, can be prepared in a process-specific manner by abrasive wet-jet cutting. The aim is to reduce defects in the cutting edge and to produce a defined cutting edge micro-shape.

The research project "Simulation-based design and manufacture of graded cutting edges on cutting tools" (StrahlSim) is a cooperation project between the Institute of Machining Technology of the Department of Mechanical Engineering and the Virtual Machining group of the Department of Computer Science. In a predecessor project (BI 498 89-1), the simulative mapping of material removal at tool cutting edges by compressed air wet-jet machining was already investigated. Based on the results obtained, a system for the simulation of graded cutting edges on complex cutting tools is now to be developed. The aim of this simulation-based design of graded cutting edges is to enable high-performance drilling tools whose cutting edge micro-shape is variably adapted to the conditions changing over the drilling tool diameter with respect to cutting speed and changing wedge angle.