Fundamental investigations on disturbing the regenerative effect in milling processes through the targeted design of tools with asymmetric dynamic properties

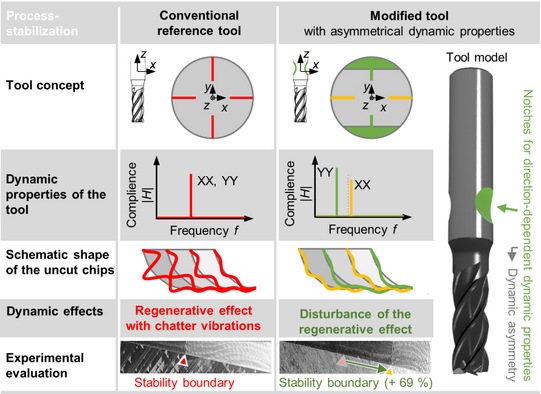

The research project "Fundamental investigations on disturbing the regenerative effect in milling processes through the targeted design of tools with asymmetric dynamic properties" is a collaborative project between the Institute of Machining Technology of the Department of Mechanical Engineering and the Virtual Machining group of the Department of Computer Science and investigates the disturbance of the regenerative effect in milling processes by using milling tools with direction-dependent dynamic compliance (AsymWZ). This will be realized by introducing slots into the tool shank, which affects the modulation of the chip thickness. As a result, different natural frequencies of the tool are excited during consecutive tooth cutting operations. Each cut is therefore still influenced by dynamic effects, but the resulting chip thickness variation, i.e. the influence of the chip thickness due to vibrations, no longer corresponds directly to the natural frequency of the cutting tooth.

The fundamental interaction mechanisms will first be investigated in experiments. Subsequently, a methodology for the specific design of AsymWZ will be developed on the basis of a geometric physically-based process simulation. The focus of the experimental analyses is on the influences of AsymWZ on the process forces, the occurring vibration modes, frequencies and amplitudes, the condition of the manufactured surface and the tool life. A central research question is therefore the investigation of the process-stabilizing effect of AsymWZ. Based on this, process models are to be developed which allow a simulation of the process dynamics taking into account the asymmetric dynamic properties of milling tools in the geometric physically-based process simulation. Furthermore, the tool compliance with rotating spindles at different speeds will be investigated. The extended process simulation allows an evaluation of the expected behavior of the AsymWZ at different process configurations. In particular, the stability behavior is to be analyzed in order to perform tool and process optimization on the basis of tool-modification-dependent stability lobe diagrams.