Data Mining on Sensor Data of Automated Processes

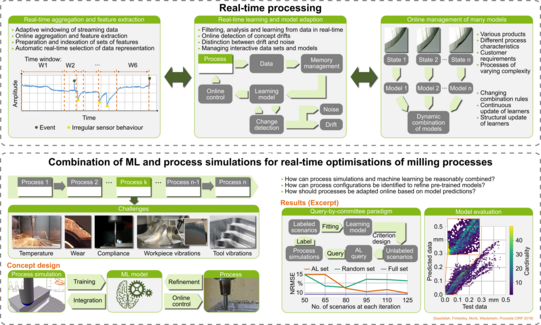

Project B3 is a collaborative project between Chair 8 for Artificial Intelligence (LS8) and the "Virtual Machining" group of Chair 14 for Software Engineering (LS14) of the Department of Computer Science and the Institute for Production Systems (IPS) of the Department of Mechanical Engineering and explores data mining in sensor data for quality prediction and control of production processes under real-time conditions. In order to meet the requirements of production, the third phase will develop methods that can adapt to changes in process conditions online. The focus is on both the optimization of individual processes based on model predictions, using NC milling as an example, which will be realized through collaboration between the LS8 and the LS14, and organizational improvements along entire process chains.

The optimization of milling processes requires methods for the online adjustment of parameter values. In order to enable real-time capable predictions, different methods for aggregation and feature extraction from time series are investigated for online application. While large amounts of data are usually available for teaching the models in large-scale production, these would first have to be obtained for individual/small-scale production with high resource requirements. Therefore, methods are to be developed with which learning models can first be trained on simulation data and then be adapted on the basis of a small amount of measurement data. Furthermore, the use of process simulations offers the possibility to analyze the limits of the model predictions, whose experimental investigation cannot be carried out for safety reasons. In addition, the learned prediction models will be adapted online based on the detection of process changes. For this purpose, methods will be developed that detect process-related shifts in the distribution during process conduction and continuously adapt learned models for subsequent processes in real time.